INTRODUCTION

Most structures have concrete as their

principal materials, used in one of the following forms:

- reinforced concrete

- prestressed concrete

- mass concrete

_______________________________________________________________________

What is concrete?

This following video shows us "WHAT IS CONCRETE" ENJOY~

Basic desired properties of concrete

(a) good workability when the concrete is fresh (newly mixed); i.e, the concrete can be transported from the mixer, handled, placed in the moulds (or formwork) with cover of oilly surface and compacted satisfactorily;

(b) high strength and hardness;

(c) adequate durability.

Mix proportions of concrete

The proportions of the constituent materials, by volume, in freshly mixed concrete:

(a) 6 -16% cement

(b) 12-20% water

(c) 20-30% fine aggregate

(d) 40-55% coarse aggregate

The properties of concrete are affected by the amounts of the constituents, i.e. the mix proportions. Measuring exact volumes of the materials is difficult. Therefore the mix proportions are usually expressed as the weight of each material required in a unit volume of the concrete production., usually in kg/m3.

The mix proportion by weight are:

Cement 150-600kg/m3

Water 110-250kg/m3

Aggregates(coarse+fine) 1600-2000kg/m3

The water/cement ratio is an important factor influencing many of the concrete properties.

_______________________________________________________________________

CEMENT

Production of cement (Portland cement)

Portland cement usually refers to the Ordinary Portland cement(OPC) is the most common type of cement being used. The important ingredients in the manufacture of

cement are calcium oxide (CaO) and

silicon dioxide (SiO2 ) or silica. Calcium oxide occurs

naturally in various form of calcareous calcium carbonate (CaCO3),

eg. chalk and limestone, while silica is found in argillaceous clay or shale..

As huge quantities of these materials are required in the manufacture of

cement, cement plants are normally sited close to a suitable source of one or

both of these. The OPC is the cheapest cement among all, hence it have been widely use to reduce the cost.

The raw materials all contain some other

components, and in particular clays contain oxides of aluminum, iron,

magnesium, sodium and potassium. Aluminum and iron oxides have a significant

effect on the manufacture and composition of the resulting cement.

The

production process

Chalk & clay reduced to particle sizes ≤ 75 µm

│

Mixed in the required proportion

│

Mixture either mixed with water to

form a slurry or dried as powder

│

WET PROCESS DRY

PROCESS

┌──────────────────────┐

Slurry fed into higher Dried powder preheated

end of inclined rotary kiln and some calcining

│

in heat exchangers

│ │

Heated as it passes down the Mixture fed into higher

kiln under combined action

of end of inclined

rotary kiln

rotation and gravity

│

│

Mixture under increasing

Mixture under increasing temperature temperature undergoes

as it passes down the kiln undergoes 2 chemical changes

4 physical & chemical

changes │

│

1. Calcining

1. Drying │

│ 2. Clinkering

2. Preheating

│

3. Calcining

│

4.

Clinkering (or burning) (see Fig 13.1)

Calcining – base materials are

heated to form oxides;

CaO

(lime) = C

SiO2 (silica) = S

Al2O3 (alumina) = A

Fe2O3 (iron oxide) = F

Clinkering – oxides at high

temperatures combine to form compounds mainly

calcium

silicates, calcium aluminates and calcium aluminoferrites

The final products of the above processes, in

the form of clinkers, are chiefly the calcium silicates and aluminates and smaller

amounts of other compounds;

Tricalcium

silicate = C3S

Dicalcium

silicate = C2S

Tricalcium

aluminate = C3A

Tetracalcium

aluminoferrite = C4AF

Each grain of cement consists of a mixture of

the above compounds.

After cooling a small amount of gypsum (calcium

sulfate dehydrate, CaSO4.2H2O) is added to the clinker

before the mixture is ground to a fine powder. The purpose of gypsum is to

retard the curing process so as to prevent immediate stiffening of the cement

paste during hydration.

The composition of the clinker determines the

types of Portland cement.. The principal compounds (derived from their oxides)

are C3S and C2S and these together normally amount to ¾

of the content of the cement (see Table 13.1).

Cement

A – ordinary Portland cement

Cement

B - early strength cement

Cement

C – low heat cement

Cement

D – sulphate resisting cement

Hydration

What is hydration?

- the chemical combination of cement and water

Initial period

after mixing

|

Between 2 – 4 hrs after mixing

|

Between 3-10

hrs after mixing

|

Between 7-28

days after mixing

|

28 days till

many months

|

fluidity of cement

and water paste constant

|

initial set – paste starts to stiffen

but no strength

|

final set – paste starts to harden and

gain strength

|

rate of strength gain rapid

|

hardened cement continues to gain strength

but at a slower rate

|

See Fig 13.3

Heat is given off during the setting and early

hardening of cement paste (concrete).

Fig 13.2 shows a typical graph on the heat

given off during hydration of cement. Immediately after mixing, there is a high

but short peak (A) of heat released, lasting only a few minutes. This quickly

declines to a low constant for the dormant period when the cement is relatively

inactive; this may last for up to 2 or 3 hours. The rate of heat released start

to increase rapidly at a time

corresponding to the initial set. This reaches a peak (B) sometime after the

final set. The reactions then gradually slow down, with sometimes a short spurt

of heat release after 1 or 2 days giving a narrow peak (C).

The behavior of the aluminates and silicates is

particularly important in the early stages of hydration;

1) C3A

reacts violently with water, resulting in immediate stiffening of the paste and

giving off great amounts of heat. That

is why gypsum is added to slow down the reaction.

C3A gives the cement (concrete) the

early initial strength.

2)

Between C3S and C2S, the former is the faster to

react giving high early strength to the cement (concrete).

3) C2S

reacts much more slowly and it contributes importantly to the long-term

strength of hardened cement.

As C3S and C2S form the

bulk of the unhydrated cement, their hydration products give the hardened cement most of its significant engineering

properties such as strength and stiffness. See Fig13.4.

Water/cement ratio is the ratio of the weight of the water to the weight of the cement. Lower water ratio lead to the increase of strength and durability of the concrete.

Modifications of Portland cement.

The rate of heat output and timescales of

setting and strength gain of cement govern some of the critical operations in

concrete practice;

-

the transport of fresh concrete

-

the placing of fresh concrete

-

the removal of formwork

Different types of Portland cement are produced

to meet the above requirements

Types of Portland Cement

Ordinary Portland Cement

This is the most widely used in construction site as it is cheaper.

Rapid-hardening Portland Cement

Rapid-hardening properties can be achieved by;

1. Having higher C3S and lower C2S

content in the cement.

By

having higher C3S which develops earlier strength compared to C2S(as

shown in

Fig 1.4), the cement paste (concrete) gain

strength more rapidly than ordinary Portland cement.

2. Grinding the cement clinkers to finer

particles.

|

| FIG 1.4 |

Being more finely ground, rapid-hardening

cement has greater surface area for hydration , thus it develops strength

more rapidly.

In cold weather, the high rate of heat output helps to prevent damage by frosts. However, the higher rate of heat output in the early stages of hydration will increase the risk of thermal cracking in large pours.

Ultra-high early strength Portland cement

In this cement, the cement clinkers are ground

to extremely fine particles. Concrete made with this cement achieves the 3-day

strength of rapid-hardening cement in 16 hours and its 7-day strength in 24

hours. Even higher early strength can be achieved by steam curing.

Low-heat Portland cement

This cement is required for thick concrete

work, where the heat generated by ordinary cements will be excessive and lead

to serious cracking. It is manufactured by either;

1. Less finer grinding of cement clinkers, or

2. Lower C3S and higher C2S

content in cement.

Sulphate resisting Portland cement

This cement is used where there is presence of

sulphates (sulfates) from external sources, such as in industrial wastes,

sulphate bearing soils and in sewage wastes.

Sulpahtes react chemically with the hydration

products of calcium aluminates, causing cracking and loss of strength in the

hcp. The solution is to reduce tricalcium aluminate (C3A) in the

cement during manufacture (not exceeding 3.5%).

White Portland cement

The gray color of Portland cement is due to

ferrite (C4AF) in the limestone or clay. White cement is made from non- ferrite

containing material – white china clay. White cement is more expensive than

normal Portland

This is made by adding about 30-35% by weight

blast furnace slag to ordinary Portland cement (opc) clinker before grinding.

The rate of hardening of this cement in the first 28 days and the heat evolved

is less, so the cement is not suitable for use at low curing temperatures.

However, the strength of mature concrete is the

same with concrete made from opc. It has good resistance to dilute acids and

sulphates and can be used for construction in sea water.

Pozzolanic cement

This cement is made from pulverized fuel ash

and opc. Pozzolanic cement is a low-heat cement – initially slower in hardening

but attains strength equal to that of opc after 3 months. Good resistance to

sea water and sulphates (sulfates).

Other types of cement (non Portland cement)

High alumina cement

Bauxite and limestone are fused in

reverberatory furnaces. These are cooled and the extremely hard product is

broken and ground to cement.

High alumina cement is grey-black (different

from Portland cement). This cement is resistant to sugar, oils, fertilizers,

beer, acids and sulphates, making it suitable to be used in places where such

materials are present. However its resistant to caustic alkalis (sodium and potassium

hydroxides) is low.

Supersulphated cement

It is made by grinding together 85-90 % of

blast furnace slag, 10-15% sulphate and 1-5% Portland cement clinker.

Resistance to acids is high and unlike high

alumina cement it is also resistant to caustic alkalis. It is a low-heat cement

suitable for mass (thick) concrete and for work in hot climates. As it is

low-heat, early strength development is slow, particularly in cold weather, but

at later ages strengths are at least equal to those of Portland cement mixes.

Admixtures for Portland cement.

Admixtures - chemicals that are added to the concrete before or during

mixing. They significantly change its

fresh, early age or hardened state of the concrete. The popularity in their use

has increased considerably in recent years.

There are 5 distinct types of admixtures;

-

plasticizers

-

superplasticisers

-

accelerators

-

retarders

-

air entraining agents

Plasticizers

These are workability aids which increase the

fluidity (or workability) of a concrete (cement) paste. Plasticizers are polymers, which are absorbed onto the surface

of cement grains with an ionic group pointing outwards. The negatively charged surfaces cause the

mutual repulsion of the cement particles, thereby dispersing the particles and

releasing entrapped water to give greater fluidity (see Fig 14.1).

Plasticizers are also known as water-reducers,

since they can produce a concrete (or hcp) with the same workability at lower water/cement

ratio. The lower water/cement ratio increases the strength of the concrete with

the same cement amount.

Undesirable secondary effects of plasticizers;

-

delaying (retarding) the set

-

decreasing early strength gain

-

entrain (trap) air in the form

of air bubbles

-

contain impurities affecting

strength of hardened concrete.

Superplasticisers

Also known as high-range water reducers.

Superplasticisers are used to achieve increases

in fluidity and workability greater than those obtainable with plasticizers.

They are manufactured to higher standards of purity – can achieve substantially

higher primary effects without significant undesirable side-effects.

Accelerators

Used to increase the rate of hardening of

cement paste, thus;

-

enhancing early strength gain

-

reducing the curing time for

concrete placed in cold weather

-

reducing setting time

Since accelerators increase rate of setting,

resulting in high rate of heat evolution, they should only be used in cold

weather.

Calcium chloride (CaCl2) was the most

commonly used accelerator as it was effective and readily available. It

accelerates both the initial and final setting of cement. It is no longer

recommended to be used in reinforced concrete (rc) as it lead to corrosion of

embedded steel reinforcement. A number of alternative chloride-free

accelerators are now used based on calcium format, sodium aluminate or

triethanolamine.

Retarders

Retarders delay the setting time of a cement mix. Their uses include;

-

counteracting the accelerating

effect of hot weather

-

controlling the set in large

pours, where concreting may take several hours

-

delaying the set where concrete

has to be transported over long distances

Admixtures based on sugars (sucrose), starches,

citric acid, zinc oxide or boric oxide are used to retard the setting of

cement.

Air entraining agents

Air entraining agents (AEAs), when added,

entrain a controlled quantity of air in the form of microscopic, discontinuous

and uniformly distributed bubbles in the cement paste.

The primary effect of entrained air provides

resistance to frost (freeze-thaw in temperate climate), which will otherwise

lead to progressive deterioration of the concrete (cement).

Air entrainment has 2 important secondary

effects;

-

increase in workability of mix;

the air bubbles act like small ball-bearings

-

increase in porosity results in

drop in strength, but the improvement in workability means the loss can be

partially offset by reducing the water/cement ratio.

Air entrainment can be achieved by adding

vinsol resins, alkylsulfonates and

alkylsulfates.

Damp-proofing admixtures

Damp-proofing admixtures prevent water movement

by capillary action. Technically they should not be called waterproofing

admixtures

_______________________________________________________________________

AGGREGATES

Aggregates are added to cement with water to

form concrete. Usually they occupy about

65-80% of the total concrete volume.

Reasons for using aggregates in concrete;

-

they reduce the costing of concrete

-

they reduce the heat output, hence, reduce thermal stress

-

they reduce shrinkage of

concrete

-

they help to produce a concrete

(when fresh) with satisfactory plastic properties

Desirable properties of aggregates;

-

they must be sufficiently strong

-

clean, free from constituents

which can react harmfully with cement

-

have small or no moisture

movement

-

be well graded

- right shape and texture so as not to adversely affect the properties of fresh and hardened concrete

- right shape and texture so as not to adversely affect the properties of fresh and hardened concrete

-

low thermal conductivity

Strength

Normal concrete strengths are lower than those

of the natural aggregates. Most aggregates are stronger than the concrete

strength designed or specified. In fact, aggregates of moderate and low

strength reduce the stress in the cement paste and increase the durability of

concrete.

Cleanliness

Aggregates should be free from significant

quantities of substances which;

-

are chemically incompatible

with cement, eg sulfates and organic matter

-

reduce bond with aggregate, eg

clay and oil

-

expand, eg bituminous coal,

-

decompose, eg organic matter

-

attract moisture, eg salt

-

cause staining, eg pyrites

Porosity and absorption of water

Aggregates contain pores which can absorb and

hold water. This is acceptable as long as there is no or little moisture

movement.

Before concrete mixing, aggregates can be in

one of the 4 moisture conditions as shown in Fig 16.4;

1. completely dry

2. air dry, pores partially

filled with water

3. saturated with water and

surface dry

4. wet with excess water on

surface

What will happen when

aggregates in the above conditions are mixed in concrete?

Which moisture condition is the

most desirable?

What is grading of an aggregate?

The proportions of the different sizes of

particles, expressed as percentages by

weight passing various sieves.

Aggregates which are retained on a 5mm BS sieve

and bigger are termed coarse aggregates, while those passing 5mm sieve are

termed fine aggregates.

Aggregates are described by their maximum size,

graded down, eg 14mm, 20mm or 40mm.

It is important to use well graded aggregates

in a concrete mix to achieve the following:

-

the various sizes of particles

interlock, leaving the minimum volume of voids to be filled with cement

-

the particles flow together

readily, ie the mix is workable

-

a lower water/cement ratio

resulting in higher strength of hardened

concrete

-

maximum density for good

strength and durability

BS 882: 1992, Specification for Aggregates from natural sources for concrete, British

Standard, gives grading limits for the various particle sizes (see Table

16.1). Aggregates for use in concrete must fall within the limits of the

grading curves for coarse and fine aggregate. Fig 16.2 shows the both coarse and fine aggregates.

The coarse aggregate can be either;

-

single size where nearly all of the

particles are within 2 successive sizes, eg 5-10mm, 10-20mm or 20-40mm

-

graded where the smallest size is 5mm,

e.g. 5-14mm, 5- 20mm or 5-40mm.

The range for fine aggregate is wide. The BS

standard subdivides this into 3 divisions of;

-

fine

-

medium

-

coarse

Sieve analysis does not take into account

particle shape, but this does influence the void content of aggregate. More

rounded particles will pack more efficiently and will therefore have a lower

void content.

Is there an ideal grading which is applicable

to all aggregates?

No, for important work, tests need to be

carried out to determine the grading (for the particular type of aggregate)

which gives maximum workability, economy, density, strength and durability in

the concrete.

As a guide, a ratio of 1 fine aggregate : 1½ to 3 coarse aggregate

is satisfactory.

_______________________________________________________________________

CONCRETE

The

study of concrete concerns with;

-

Properties of fresh concrete

-

Early age properties of

concrete

-

Properties of hardened concrete

-

Concrete mix design

Properties of fresh concrete

Properties of concrete when freshly mixed,

between placing and setting, and during early stages of hydration. These properties have significant effects on

the long term performance of the hardened concrete.

The main properties of interest:

1.

Fluidity – being capable of being handled and of flowing into the formwork

and around reinforcement;

2. Compatibility

– the air entrapped during mixing, transporting and handling should be

capable of being removed;

3.

Stability or cohesiveness – the concrete should remain as a homogeneous uniform

mass.

Properties (1) & (2) – fluidity and compatibility

– are combined into the property called workability.

What is the definition of workability?

‘The property of freshly mixed concrete or

mortar which determines the ease and homogeneity with which it can be mixed,

transported, placed, compacted and finished’

In general, higher workability concretes are

easier to mix, transport (especially, place and compact. Higher workability of

concrete can be achieved by one or a combination of the following:

1. Use of a well graded aggregate.

2. Use of smooth and well rounded, rather than

irregularly shaped aggregate.

3. Use of air-entraining admixtures.

4. Use of plasticizers and superplasticisers.

5. Higher water/cement ratio.

The undesirable side-effects from the use of

some of the above methods;

-

Use of smooth and well rounded

aggregate lead to lower strength, but this can be offset by lower water/cement

ratio.

-

Higher porosity arising from

the use of air-entraining admixtures results in lower strength. However, this

loss is partially offset by the gain in strength by lower water/cement ratio.

-

Use of higher water/cement

ratio is the simplest way to achieve higher workability but there is the risk

of segregation of aggregate which results in lower strength.

Workability Tests

The most common tests are;

1. Slump test (see Fig 17.2)

2. Compacting factor test (see Fig 17.3)

Procedure to determine workability of fresh concrete by compacting factor test.

i) The sample of concrete is placed in the upper hopper up to the brim.

ii) The trap-door is opened so that the concrete falls into the lower hopper.

iii) The trap-door of the lower hopper is opened and the concrete is allowed to fall into the cylinder.

iv) The excess concrete remaining above the top level of the cylinder is then cut off with the help of plane blades.

v) The concrete in the cylinder is weighed. This is known as weight of partially compacted concrete.

vi) The cylinder is filled with a fresh sample of concrete and vibrated to obtain full compaction. The concrete in the cylinder is weighed again. This weight is known as the weight of fully compacted concrete.

ii) The trap-door is opened so that the concrete falls into the lower hopper.

iii) The trap-door of the lower hopper is opened and the concrete is allowed to fall into the cylinder.

iv) The excess concrete remaining above the top level of the cylinder is then cut off with the help of plane blades.

v) The concrete in the cylinder is weighed. This is known as weight of partially compacted concrete.

vi) The cylinder is filled with a fresh sample of concrete and vibrated to obtain full compaction. The concrete in the cylinder is weighed again. This weight is known as the weight of fully compacted concrete.

3. Vebe test

4. Flow table test (see Fig 3.4 – fig 17.5)

4 inter-related phenomena are important during

the period after placing and setting of concrete;

- bleeding

- segregation

- plastic movement

- plastic shrinkage

Segregation and bleeding

Segregation – the denser constituents, larger

aggregate and cement particles falling to the lower part of the pour.

Bleeding

– upward displacement of water after placing, appearing as a layer of water on

the top

surface of concrete.

Problem associated with segregation;

-

the upper part of the placed

concrete will have more fines, resulting in the upper part of the hardened concrete being

weaker than the lower part (see Fig 18.2)

-

Problems associated with bleeding;

-

the layer of water at the top

either evaporates or is re-absorbed into the concrete with hydration, resulting

in a net reduction of the original concrete volume.

-

The cement paste just below the

surface of the placed concrete becomes water rich and therefore hydrates to a

weak layer.

-

The upward migrating water can

be trapped under aggregate particles, causing local weakening of the zone

between the cement paste and aggregate, resulting in overall loss of concrete

strength.

Plastic

movement/settlement

Movement increases with the

richness of a mix and with higher water/cement ratio. Greater movement in the

fresh concrete occurs near the surface of a pour. If there is any local

restraint to this movement (e.g. presence of horizontal reinforcing bars, then

plastic settlement cracking can occur. This appear as vertical cracks form

along the line of the bars (see Fig 18.3)

This is due to quick loss of

water from the surface of concrete while the concrete is still plastic. The

restraint of the lower mass of concrete on the shrinkage at the surface cause

tensile strains to be set up in the surface region, resulting in plastic

shrinkage cracking (see Fig 3.7 – fig 18.3). Tendency to plastic shrinkage

cracking will be encouraged by greater evaporation rates of surface water due

to;

-

higher concrete temperatures

-

higher ambient temperatures

-

concrete being exposed to wind

Curing

What is curing?

The protection of concrete from moisture

loss after placing and for the first few

days of hardening.

Purpose of curing?

-

Reduce or eliminate plastic

shrinkage cracking

-

Ensure adequate supply of water

for continued hydration and strength gain.

Curing methods

o

Spraying or ponding surface of

concrete with water.

o

Protecting exposed surfaces

from wind and sun by windbreaks and sunshades

o

Covering surface with wet

Hessian or polythene sheets

o

Applying a curing membrane;

spray applied resin seal, to exposed surface of concrete

Properties of Hardened Concrete

The

properties of hardened concrete that are of

interests are:

-

permeability

-

frost resistance

-

resistance to abrasion

-

strength

Among

the above properties, strength is the most important single property, since the

first (and most important) consideration in structural design is that the

structural members must be capable of carrying the imposed loads.

Permeability

Concrete

which is made with low water/cement ratio and well-compacted has good

resistance to the absorption of water, i.e. low permeability. A concrete that

is low in permeability has high durability.

Frost resistance

Concrete

can be damaged by expansion of ice crystals (in cold weather) form in capillary

pores or cracks. Air-entrainment admixtures form discontinuous minute bubbles

which improve resistance to frost.

Resistance to abrasion

Depends

upon the hardness of the aggregate particles and the ability of the mortar

matrix to retain them (i.e. minimal bleeding).

Strength of hardened concrete

As

mentioned earlier, strength is the most important single property. Strength of

concrete can be compressive or tensile.

Cracking (failure) pattern

in normal strength concrete (see Fig 20.5)

Necessary to understand the

cracking pattern

Factors influencing

strength of concrete

What

are the factors influencing strength of concrete?

-

Water/cement ratio

-

Effect of age

-

Temperature during hydration

-

Humidity during curing

-

Aggregate properties

Water/cement ratio

For

a fully compacted concrete, the

strength of concrete is inversely related to the water/cement ratio (see Fig

20.7).

Limitations

of the above relationship;

-

at low water/cement ratio, the concrete

becomes less workable and increasingly more difficult to compact

-

the difficulty in compacting

leads to increasing air being entrapped in concrete

-

the entrapped air will reduce

the concrete strength; each 1 % of entrapped air by volume will reduce the

strength by 6% (see Fig 3.8 – shown by dashed lines)

How

can the difficulty in compaction and poor workability be overcome, without

increasing the water/cement?

-

use of more efficient method,

-

use of plasticizers or super

plasticizers

-

Use of a well-graded aggregate

-

Use of air-entraining admixture

Effect of age

The

degree of hydration increases with age; the older the concrete (in the presence

of moisture) the greater the strength . The strength at 28 days is often used

to characterize the concrete for specification and compliance purposes.

However,

it is important to note that the rate of gain of strength varies with;

-

water/cement ratio

-

rate of hydration

-

cement fineness

Humidity

For

adequate curing (strength gain) it is necessary to have a humid environment.

Concrete cured with the presence of water will achieve greater strength than if

cured in air for some or all its life

Aggregate properties

For

normal concrete, the strength of the cement paste/aggregate bond (transition

zone) has the dominant effect on strength of concrete. This bond is influenced by;

-

aggregate mineralogy

-

aggregate surface

Increase

surface roughness can improve the bond, due to greater mechanical interlocking.

Therefore concretes made with crushed rocks are typically 15% stronger than

those made with uncrushed gravels (provided all other mix proportions are the

same).The use of larger maximum aggregate size reduces the concrete strength

due to lower overall surface area with a weaker transition zone (bond).

Strength tests

Types

of strength properties in hardened concrete;

-

compressive

-

tensile

-

torsional

-

fatigue

-

impact strength

-

multiracial loading

Different

test methods/techniques are used in different countries. Two main objectives of

strength testing are;

1.

Quality control

2.

Compliance with specifications.

Tests

can be:

-

mechanical tests to destruction

-

Non-destructive tests, which

allow repeated testing of the same specimens and thus make possible a study of

the change of properties of the concrete with time.

Compressive strength tests

Is

the most common tests on hardened concrete. 2 types of compression test

specimens are used;

-

cubes; used in Great Britain,

Germany and many countries in Europe,

-

cylinders; used in the US,

France, Canada, Australia and New Zealand

The

procedure for preparation of cubes;

1. Fill the mould in 3 layers; each

layer of concrete to be compacted by a vibrating hammer, vibrating table or by

a 25mm ramming rod with no fewer than 35 strokes,

2.

Trowel smooth’s the top surface of the cube,

3.

Store the cube undisturbed for 24±4 hours,

4.

At the end of the period, the mould is stripped and the cube is further

cured in water.

Specimens are usually tested for 7,

14 and 28-day strengths.

Testing procedure;

1.

The cube is taken out from the curing tank and allows drying for 30

minutes,

2.

It is then placed with the cast faces in contact with the platens of the

testing machine,

3.

The load on the cube is applied at a constant rate of stress of 0.2-0.4

MPa/sec, until failure of cube.

Cylinder test

The

standard cylinder is 150mm diameter x 300mm high. Cylinders are cast in moulds

generally of steel or cast-iron. Making and testing of cylinders are similar to

those for cubes, with the difference that treatment need to be made to the

trowelled end of the cylinder to ensure that the surface will be in good

contact with the platen of the testing machine. This is to ensure even

distribution of the load over the surface area. Treatment is usually done by

capping, with a suitable material like high-strength gypsum plaster or high

early strength cement paste.

Standard

cylinders have height/diameter (h/d) ratio of 2, but sometimes specimens could

be of other ratios, particularly the case where samples are cored from in situ

concrete, where the height of the core varies with the thickness of the slab or

concrete member. With cylinders where the h/d ratio is less than 2, it is

necessary to determine the strength of the concrete by multiplying the test

readings with the correction factors ( see Table 12.1).

Tensile strength tests

Direct testing of concrete in

uniaxial tension (Fig20.3a) is difficult;

Reasons:

-

relatively large sections are

required to be representative of the concrete

-

concrete is brittle, therefore

making it difficult to grip and align

Fig 20.3a 1

For the above reasons, tensile strength testing of concrete is done by indirect tests;

- Splitting test

- Flexural test

Splitting test

Splitting test

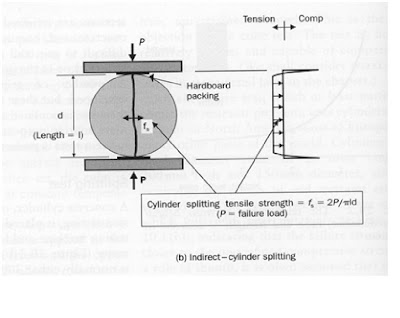

A concrete cylinder of normally 300 or 200mm long by 150mm or 100mm diameter, is placed on its side in a compression testing machine and loaded across its vertical diameter (see Fig 20.3b). Load (P) is then applied on the specimen until failure occurs by a split or crack along the vertical plane. The cylinder splitting strength is given by;

ƒs = 2P/πld (see Fig 20.3b)

However it should be noted that ƒs is higher than the uniaxial tensile strength.

The video above shows splitting tensile strength test for concrete

Flexural test

A rectangle length of concrete of x-section usually 100 or 150mm is simply supported over a span L (usually 400 or 600mm). Load is applied at the third points (see Fig20.3c) and failure occurs when a flexural tensile crack at the bottom of the beam propagates upwards through the beam. Maximum tensile stress, ƒb (known as modulus of rupture) is calculated as;

ƒb = PL/bd2

The modulus of rupture is greater than the uniaxial tensile strength. See Fig 3.11 – fig 20.4 for a comparison of the direct and indirect tensile strength measurements.

The video above shows flexural strength test for concrete

Non-destructive testing of hardened concrete

Non-destructive

(or sometimes known as in situ) testing is used for 2 main purposes;

·

in laboratory studies, where it

is useful for repeated testing of the same specimen to determine the change of

properties over time

·

to assess the properties of

concrete in an existing structure, e.g. uniformity of concrete or after damage

by fire or when a change in use is proposed.

It

is important to note that a single non-destructive test rarely gives a single

definitive answer, and engineering judgment is required in interpreting the

results.

Limitations

to non-destructive tests;

Rebound (Schmidt) hammer test

This

is a simple apparatus contained in a hand-held cylindrical tube (see Fig 3.12 –

fig 22.1), and consists of a spring-loaded mass which is fired with a constant

energy against a plunger held against the concrete surface. Procedure in

testing;

·

the surface to be tested first need to be

smoothened by polishing

·

the plunger is pressed (at right

angle) against the concrete face

·

the spring is released by

pressing the release button

·

the rebound number on the scale is recorded

A

higher rebound number indicates a harder surface. However, there is

considerable local variation due to the presence of coarse aggregate particles

or voids just below the surface. Therefore, a number of readings (usually 10

over an area of 150mm dia.) must be taken and averaged.

The

test does not give a direct measure of the strength of the concrete being

tested. Instead indication of the strength is provided by the correlation chart

between rebound number and compressive cube strength (see Fig 22.2). This

correlation depends on;

·

the aggregate type used in the

concrete;

·

moisture condition of the surface.

This

is a versatile and popular test for both in situ and laboratory use. It

involves measuring the time taken for an ultrasonic pulse to travel through a

known distance in concrete. The ultrasonic pulse is generated by a

piezo-electric crystal housed inside a transducer which is then detected by a

second similar transducer. The

instrumentation measures and displays the time taken for the pulse to travel

between the transducers.

Like

rebound hammer test, upv test does not directly measure the strength of the

concrete. Upv can be correlated empirically to strength, and this correlation

only gives an indication of the actual strength of the concrete being tested

(see Fig 22.6). Upv test, like the rebound hammer test, is limited by;

·

the constituent materials

·

moisture conditions

The

velocity through a harder material is higher than that through a softer

material. Hence, in in-situ testing, it is very important to ensure that

measurements are taken where there is no presence of steel bar in the path of

the pulse, which would otherwise result in a falsely low transit time.

Other non-destructive tests; like resonant frequency test, pull-off test, pull-out, penetration test, etc.

Other non-destructive tests; like resonant frequency test, pull-off test, pull-out, penetration test, etc.

1 comments:

Whether the building material used is concrete or if it is cultured stone, these professionals Nassau County Paving Stone Contractors have right expertise and equipments to do the work.

Post a Comment